Toy making dates back centuries, with some of the earliest examples being found in China and India. In the modern era, toy manufacturing has become a highly automated process, with machines handling many of the tasks traditionally associated with toy making. Toy making is still a labor-intensive process, however, and many toys are still made by hand.

There are many steps involved in making a toy. The first step is designing the toy. The toy designer may look at different types of toys, children’s interests, and popular toys to come up with a design. After the design is finalized, the toy is created by a team of people. These people may work in different departments such as engineering, manufacturing, and marketing. After the toy is created, it must be tested and made sure that it meets all safety standards.

Research

Toy companies use research to learn what children want before they create a toy. They collect data such as market trends and surveys to understand what children like, how they play, and what their needs are. After the company understands these factors, it can begin creating a toy that meets those needs.

Concept and design

Most people believe that toys are made by large, industrialized companies. In reality, the toy industry is a small and family-owned business. There are many different steps that go into making a toy. Here is a brief overview of the process:

1) A toy designer comes up with an idea for a new toy.

2) The designer sketches out the idea on paper and presents it to a team of testers.

3) The team tests out the toy and makes modifications if necessary.

4) The toy is then manufactured using high-quality materials.

5) The toy is packaged and shipped to retailers.

Prototype

Toys are one of the most popular gifts for children. Not only do they provide entertainment, but they also teach important life skills. In order to make toys as safe as possible, manufacturers use prototypes to test their products before they are released to the public.

Toy manufacturing is an intricate and time-consuming process. Designs are approved by management, and then a prototype is made from clay. A sculptor will create the body first, and then a designer will add the final details. The toy may be finalized in plastic or other materials, and it is often sold to stores.

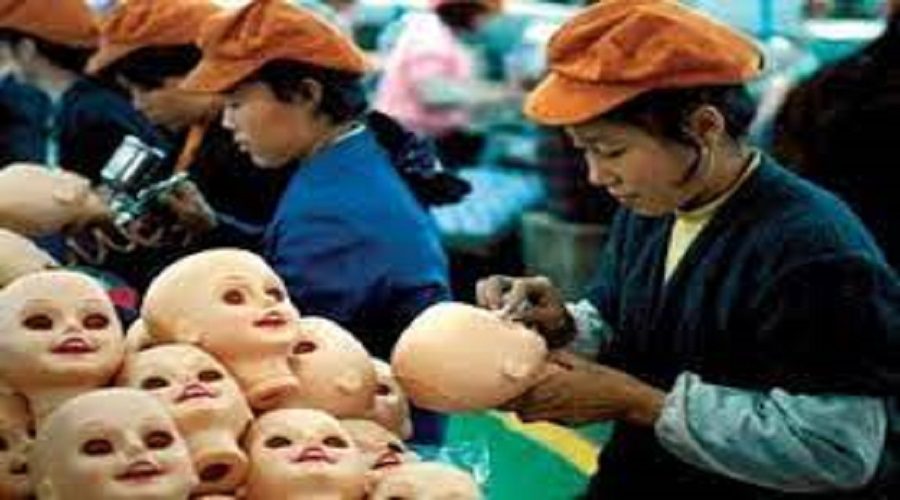

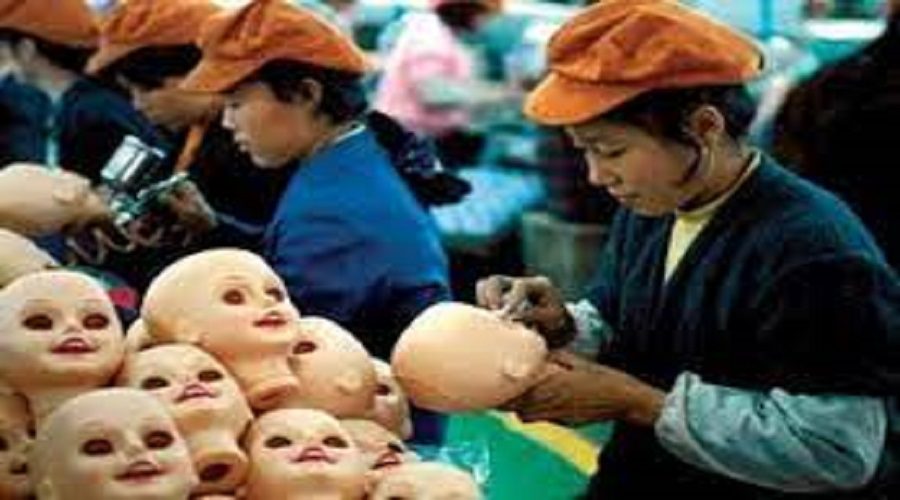

Production

Toy production is a complex process that starts with the design of a toy. In many cases, this process begins with sketches or ideas created by the toy’s creator. After the creator has come up with a preliminary design, they will work with a team of engineers to create a prototype. The next step is to test the toy’s feasibility and determine if it can be produced commercially. Once it is determined that the toy can be produced, manufacturers will begin creating batches of the product. After these are complete, they will be sent to retailers for sale.

Once a prototype has been approved, this will now be sent to the manufacturer. The manufacturer will mass-produce the toys. One of the most used methods of making toys is injection molding. Injection molding is when hot plastic is injected into a machine that creates the toy. This process can be time-consuming and prone to error, but it yields high-quality products that are easy for consumers to find and purchase.

Quality control

Quality control is important when making toys. The toy must be made with the correct materials and in the correct way. There are many steps that go into making a toy, and each step must be done correctly in order for the toy to be of high quality.

Toys are one of the most popular gifts for children. They provide entertainment and can help teach important life skills. Toys are made in a variety of ways, but some common methods include injection molding and casting. Injection molding is used to create plastic toys. These toys are usually made from a single piece of plastic and then divided into parts. The parts are injection molded one after the other, which creates a toy with very accurate details. Casting is used to create metal toys. These toys are often less detailed than plastic toys, but they are more durable. Metal toys can also be customized in many ways, which makes them more unique. Each type of toy undergoes different quality control tests to ensure that they meet the standards set by manufacturers.

Is the Idea Unique and Marketable?

The toy industry is a multi-billion dollar business and there are many different types of toys. Toys can be made in a variety of ways, from traditional manufacturing methods to innovative new methods that are being developed. It’s important to consider the idea behind the toy before deciding if it is unique and Marketable. If the idea is good, it will be marketable regardless of how it is made. However, if the idea is not good, making the toy using an innovative method may improve its chances for success.

Is It Cost-effective?

A lot of people think that it is not cost-effective to make toys because of the high cost of materials. However, there are a few different ways that toys can be made without costing a lot of money.

One way that toys can be made is by using recycled materials. Recycled materials can be used to make toys that are just as good as those that are made with new materials, but they are cheaper. This is because the manufacturing process for recycled toys is usually less complicated than it is for new toys.

Another way that toys can be made cheaply is by using 3D printing technology. 3D printing allows companies to create custom objects very quickly and cheaply. This means that companies can create a wide range of products without having to spend a lot of money on equipment or materials.

Are You Legally Protected?

Are you legally protected when buying toys? Toys are made with different materials that can have different levels of safety. The Consumer Product Safety Commission (CPSC) has set safe limits for lead, cadmium, and other toxins in toys. However, there is no federal standard for toy safety. This means that some toys may have higher levels of toxins than others. If you’re concerned about the safety of a toy, don’t buy it! There are laws in place that protect consumers from dangerous products. These laws include the Magnuson-Stevens Act and the Toy Safety Act. The Magnuson-Stevens Act sets the safe limits for lead in children’s products. The Toy Safety Act requires that all toys sold in the United States meet certain safety standards. If a toy doesn’t meet these standards, it can’t be sold in the United States.

Is It Safe?

Are electronic toys safe? It’s a question that has been on parents’ minds for years, and one that has yet to have a definitive answer. Toys are made in a variety of ways, with some using harsh chemicals and others using natural materials. While there is no evidence to suggest any specific toy is unsafe, it’s important to be aware of the manufacturing process before making a purchase.

Packaging and delivery

Toy packaging comes in all shapes and sizes, but the goal is always the same- to protect the toy from damage during shipping and storage.

To make a toy, manufacturers start with a soft plastic or metal mold. This mold is used to create a prototype or test piece of the toy. Once test pieces are created, they are used to create molds for production versions of the toy.

Molds are made in several different ways. The most common type of mold is called a sand cast mold. In this process, molten plastic is poured into the mold, and it cools quickly so that it can be reused multiple times.

Another popular type of mold is an injection-molding machine.

Conclusions

In conclusion, toys are made from a variety of materials, including plastic, metal, and rubber. Different techniques are used to create the desired toy shape, and different parts are heated or molded together to create the finished product. Toy manufacturers use a variety of methods to test and improve their toys before they are released to the public. Consumers can expect the latest and greatest in toy technology when they purchase toys from the store or online.